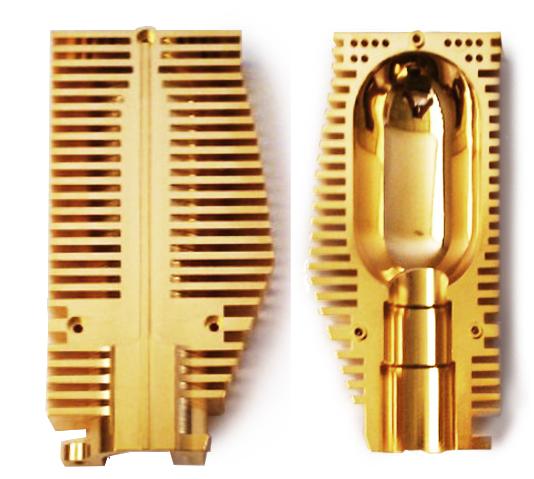

Application – Medical – Specimen Analysis – GOLD Plated

Reflective Pocket Profile & Surface Finish

Undefined Requirements on Reflectivity

K&G machined parts, Sub-Contracted Polishing & Plating

Exceeded Customer Expectations

Process controlled to achieve the undefined requirements of the reflective surface

Defense – Tank Projectile

Fin used 1 ½ deg. cant angle to create rotation of projectile

Blade area was being EDM’ed at a cost of approximately $450 per fin

K&G developed a simple solution to machine blade area

K&G’s unique approach reduced the cost of the fin by 90% saving over $1200 per round

Cost saving made the program fiscally viable for continued development

Aerospace – Transfer Pump- F-22 Raptor

Customers casting supplier had a catastrophic failure of one of their vacuum chambers

Castings were sent in 12-18 pc lots each month

Allowed our customer to meet their monthly engine build schedule

Application – Defense – 120MM Tank Round

Previous Supplier was no longer viable

Customer came to K&G to become supplier of Sabot

K&G developed more robust process that met the current cost model

Received approval of FAAT on first submission – Only supplier to ever accomplish this

Delivered product on time, eliminating any down time in assembly

Marine – High Performance Lower Units

Customer previously had lower unit skeg profiles ground by hand

Inconsistent Results & Expensive

K&G proposed the machining of the profile and then final blend

More consistent results & reduced cost

Customer now uses this process as part of their design of new lower units

K&G became supplier of choice on ALL lower units

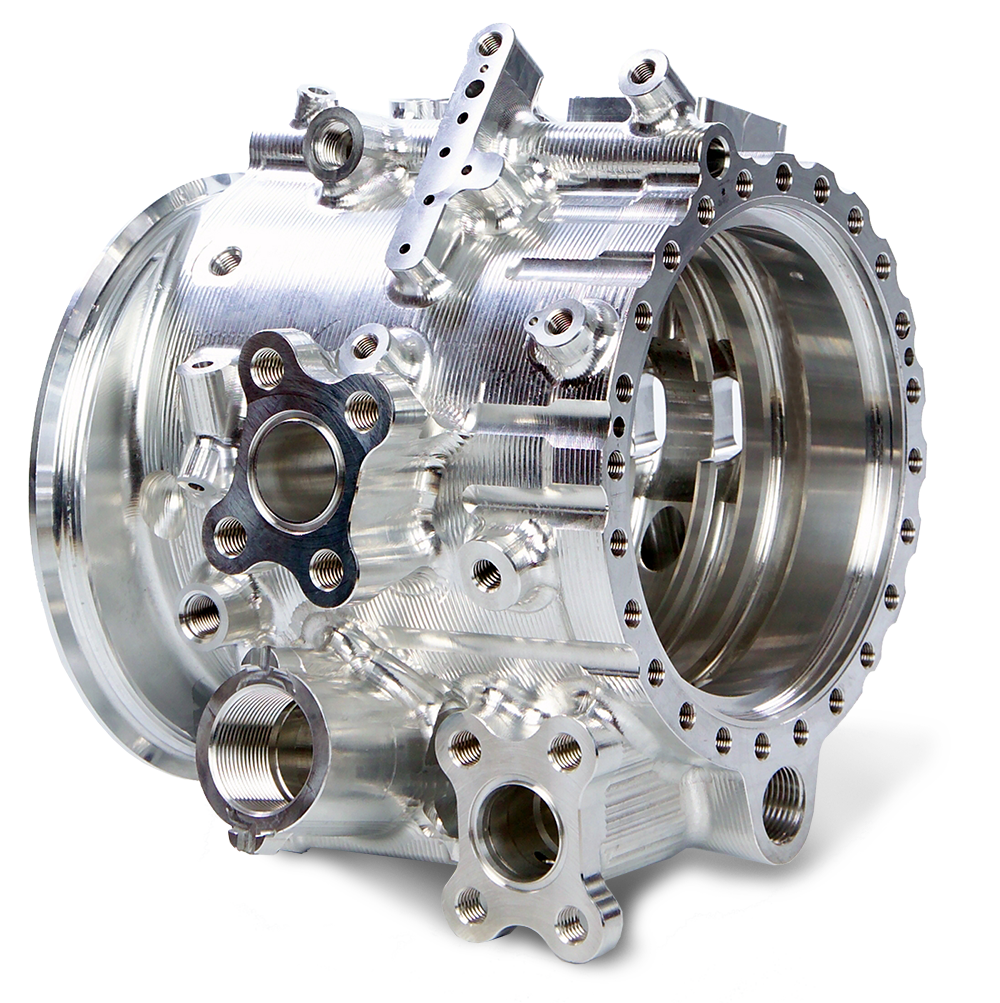

Application – Auxiliary Aircraft Fuel Pump

Machined complete from block of Forged Aluminum

Collaborated with customer on outside configuration to reduce weight & manufacturing cost

Provided quick turn-around to support compressed development time frame (1 year vs. 5 years)

Performed anodizing and sub-assembly