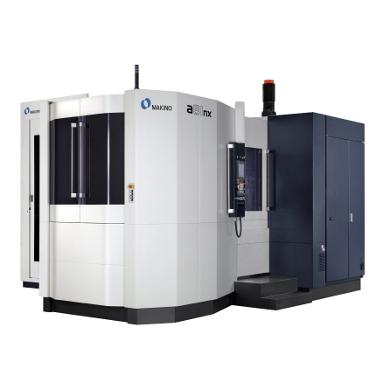

The a61nx is a 500mm, 40-taper production horizontal machining center. The a51nx and a61nx share key machine technologies that take part productivity, accuracy and machine reliability to the next level. Robust casting design and large roller-type linear guides ensure that the entire a61nx work envelope can be effectively utilized.

The 14,000-rpm high-speed, high-power spindle features 303 Nm of torque. The machines stiffness and rigidity supports thorough utilization of the spindle power and torque to tackle ferrous applications that traditionally would be run on 50 taper machines.

Again, K&G has invested in new technology. Both Machines have 20,000 RPM HSK spindles,

8 Pallet Pools, 314 tool capacity, 1,000 PSI Thru Spindle Coolant.

Investing in cutting edge technology equipment, K&G purchases a new Doosan 2600SY High Performance CNC Turning Center. This has the new 32I Control, Live tooling, Magazine Style Bar Feeder, Sub Spindle, and many other features allowing us to stay flexible and reduce costs to our customers. Because here at K&G, Metal meets the cutting edge!